Governance Assurance & Capital Stewardship

Case Study: Mining startup turnaround through advanced project management strategies

Client Overview

A leading open-pit mining operation encountered significant challenges in ensuring timely delivery and cost management due to operational inefficiencies and management-contractor disconnects.

Challenges

Management-contractor disconnect: Ineffective communication and coordination led to project delays.

Delivery delays: Significant delays were projected in delivering Run-of-Mine-Ore (ROM).

Cost overruns: Substantial budget overruns occurred due to inefficient planning and execution.

Implementation issues: Lack of detailed engineering designs and poor implementation management exacerbated delays and costs.

Assignment

TacminMadini was engaged to re-engineer the client's operations by leveraging PMI principles and advanced project management strategies to address the above challenges. While these advanced techniques are well-established in the construction of process plants and infrastructure facilities, they hold significant potential for improving mining projects as well.

Approach

TacminMadini followed a structured project management approach drawing on methodologies from the construction industry (Bridging the gap between construction and mining with advanced project management strategies) to ensure effective project execution and management:

1. Re-engineering Operations:

- Fast-tracking processes: Redesigned workflows and project schedules to expedite ROM delivery.

- Implementation plans and budget Forecasts: Developed detailed plans and accurate budget forecasts aligned with project goals.

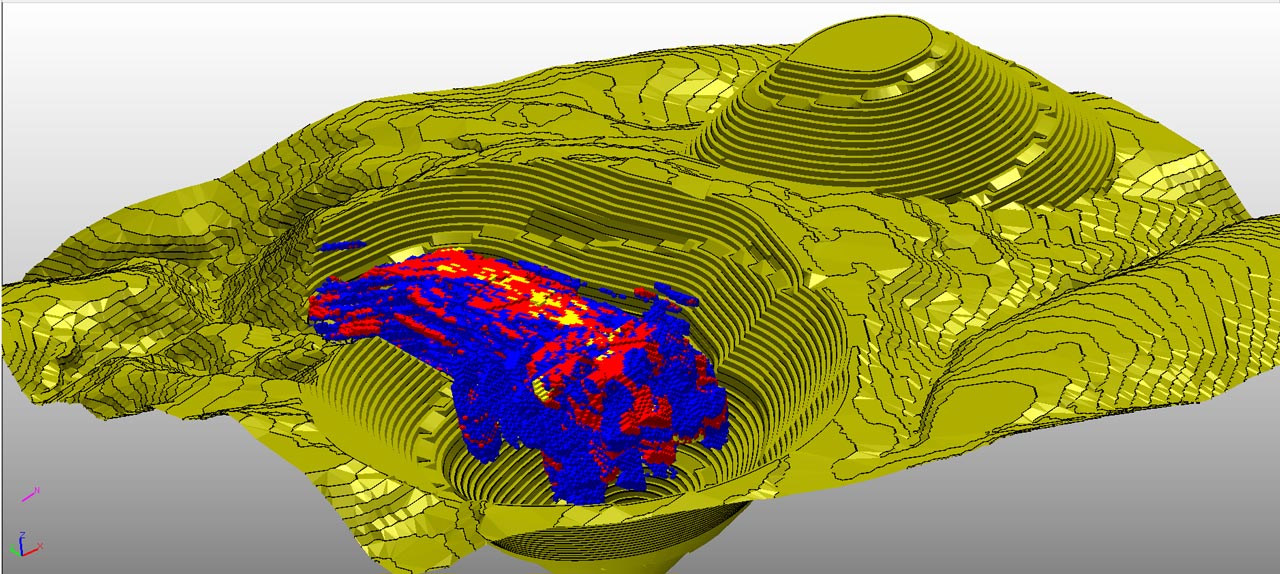

- Redesign pits and ramps: Reviewed and redesign pits and ramps which significantly reduced haul distances.

2. Equipment Capability Assessments:

- Conducted a comprehensive fleet selection exercise and benchmarked equipment design capabilities.

- Allocated appropriate resources to specific activities to optimize productivity.

- Simulated the equipment production capabilities and compiled look-ahead schedules.

3. Establishing Management Structures:

- Set up robust management structures to oversee project execution, ensuring clear roles and responsibilities.

4. Medium and Short-Term Planning:

- Developed and implemented medium and short-term engineering and planning processes to adapt to project needs dynamically.

5. Tracking and Monitoring:

- Introduced advanced tracking systems to monitor production rates and control costs in real-time, enabling proactive adjustments.

6. Contractor Management:

- Improved communication and collaboration between contractors and the client's operational management.

- Implemented effective contractor management strategies to ensure alignment with project objectives.

7. Controlling Certification and Payment Processes:

- Instituted stringent controls over certification and payment processes to ensure transparency and accountability.

8. Cost Studies and Tender Processes:

- Conducted comprehensive cost studies comparing contractor vs. owner expenses.

- Streamlined contractor tender processes and engaged in strategic price negotiations.

9. Dispute Resolution:

- Established mechanisms for resolving disputes, such as overcharges, to maintain project momentum.

Results

By applying PMI principles and advanced project management strategies as applied in the construction industries, TacminMadini achieved significant positive outcomes:

- Timely ROM delivery: Successfully met ROM delivery targets by addressing operational bottlenecks.

- Practical engineering solutions: Implemented feasible engineering designs that enhanced project efficiency.

- Training of personnel: Provided training to the client's mining personnel, enhancing their operational knowledge.

- Budget conformance: Maintained project expenses within the allocated budget, avoiding cost overruns.

- Streamlined processes: Improved management and implementation processes, leading to enhanced operational efficiency.

- Enhanced relationships: Fostered a positive and collaborative relationship between the client and contractors.

Conclusion

TacminMadini's structured approach, based on PMI principles and advanced project management tools similar to those applied during infrastructure and process plant construction, effectively bridged the gap between construction and mining operations. The comprehensive strategies implemented established a framework for future project success. This case study proves that mining operations can achieve equally successful outcomes by leveraging PMI principles and advanced project management strategies similar to those in the construction industry.

Categories

Tags

Recent Posts