Governance Assurance & Capital Stewardship

Importance of accurate ore grade predictions in mine scheduling for open-pit gold mines.

One of the key challenges in open-pit gold mining is to optimize the mine scheduling, which involves deciding which blocks of ore to extract and in what order. The quality and quantity of the ore, or the grade, is a crucial factor affecting the mining operation's profitability and sustainability. Therefore, accurate ore grade predictions are essential for making informed and optimal decisions.

However, predicting the ore grade is not a simple task, as it depends on various geological, geochemical and geophysical factors that are often uncertain and complex. Moreover, the ore grade can vary significantly within the same deposit, making it difficult to estimate the average grade for a large ore block. This can lead to overestimation or underestimation of the ore value, leading to unnecessary low confidence in the orebody and negatively impacting revenue .

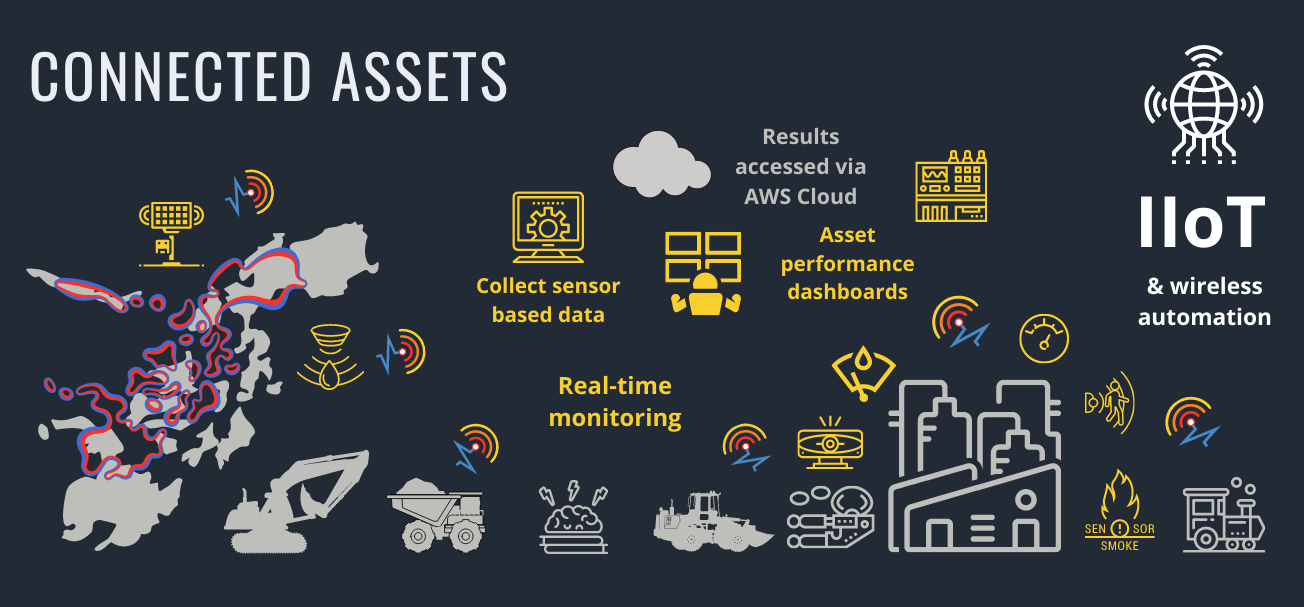

To address this challenge, some of the latest technologies and methods in data analytics, machine learning and artificial intelligence can be applied to improve the ore grade predictions. These techniques can help to integrate and analyze large amounts of data from different sources, such as drill holes, blast holes, assays, sensors, images and models. They can also help to identify patterns, trends and relationships that are not easily detectable by human experts or conventional methods. By using these advanced tools, mining engineers and geologists can gain more insights into the ore characteristics and variability, thus improving their predictions' accuracy and reliability.

Another very effective process, which we have implemented in several open-pit gold mines and consistently achieved the desired results, enabling the Client to secure projected revenue, involves restructuring the geological model and simulating mining schedules. This ensures that the equipment allocated can achieve the desired mining drop-down rate to reach and extract ore on time. In many instances, those above has demonstrated why the predicted ounces were not achieved historically and enabled us to propose timeous corrective measures.

As proven by experience, deeper open-pit mines with high ore-waste stripping ratios and complex geological structures are considerably more challenging and cannot be compromised. Consistent with our undertakings as an EPC contractor, the aforementioned is naturally what our customers expect from us during an EPC mining contract. For those reasons above, our Clients often elect to incorporate and base their financial models on our integrated ore grade schedules with equipment allocations and forecasted mining costs. For more information on our EPC models, please visit our website.

Categories

Tags

Recent Posts