Governance Assurance & Capital Stewardship

Pilot programs for owner-operator mining on conventional unit rate contract

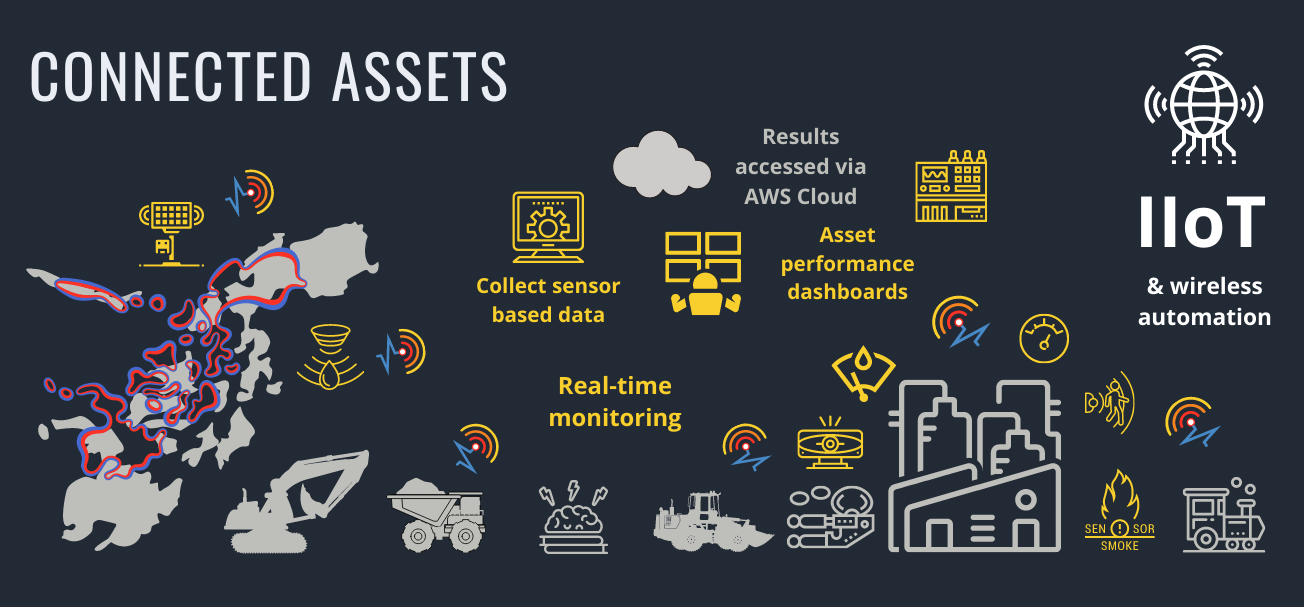

Besides the benefits of having total control over your mining, optimised costs and effective resource utilisation, owner-operator mining also kick starts the road to digital transformation in your mine from where digital technology into all areas of your business drive down costs, optimises operations and delivers value. A required component of a digital transformation is also a cultural change and mining companies specifically need to challenge the status quo and differentiate.

How often have we not witnessed the cultural change on mine sites during owner-operator versus contractor trade-off assignments in contract mining applications, simply because our owner-operator studies break down mining costs in all its components.

Cost control is the process of estimating costs to plan and adjust a budget. To accurately control costs, all expenses must be monitored and spending controlled to accommodate for any changes. Improved control over mining and costs begins with monitoring and tracking changes to expenses, which is not possible without a cost breakdown of the mining operations.

TacminMadini's CeO specialises in project time and cost overrun support that can be assigned at any stage of your project. We analyse fragmented complex processes and apply proven zero-based cost controls and state-of-the-art industry 4.0 technology during optimisation contracts.

An owner-operator pilot program begins with a zero-profit margin bid (shadow bid) comprising a breakdown of the contractors' total project value estimated from first principles using the resources employed by the contractor. Once our cost engineers have provided you with a complete cost breakdown that matches the contract value, your staff has first-hand knowledge of how the contractor's costs are made up.

In the next stage of the pilot program, our engineers will establish a link between your mine plan and costs, thereby making it possible to produce budget forecasts that are aligned with the mine plan and production schedule. At any stage of the pilot program, project outcomes can be predicted through applying what-if scenarios in the project life cycle models.

Project life cycle models are based upon sound cost engineering principles that enable us to track budget and time conformance. By closely monitoring and tracking compliance to the mine plan and production schedule will realise cost and budget conformance. Cost and budget reconciliations are done monthly in the same manner that the cost breakdown will match total contract value, the detailed monthly costs will match the contractor's monthly certificated value.

Besides the value add and knowledge gained from a pilot program, the process realizes improved mining costs and makes it possible to optimise the contractor's resources. At this point, you can either abandon the pilot program, proceed with the next stage or it can be converted into a project cost and time overrun support contract.

The next stage of the pilot program provides for commercial agreement modifications, equipment finance options and more. If you want to learn more about our pilot programs for owner-operator mining do not hesitate to make an enquiry.

Categories

Tags

- AI and IoT platform

- Construction project management software

- Contract miner

- Contractor owner trade-off studies

- Contractor to owner mining

- Cost blow-outs

- Data visualisation & analytics

- Distressed projects

- Emerging technologies

- Gain-share pain-share contract

- IoT Infrastructure

- Life of mine costs

- Mining equipment capital costs

- Mining investor

- Mining project value improvement

- Open-book cost plus contract

- Operating costs

- Operational improvement

- Owner mining

- Predictive life cycle modelling

- Project turnaround

- Real-time data management

- Shadow bids

- Total breakdown of mining costs

- Zero profit margin bid

- capital costs

- competitive tenders

- contract mining renewals

- conventional unit rate contract

- digital technology

- estimating, planning and project control software

- mine development

- on-time and within-budget completion

- project cost control

Recent Posts